Innovation

Through market research, product study, and a forward-thinking work environment, we quickly turn ideas and design concepts into reality delivering products around the world that exceed customer expectations.

- Ultrathin Inline SAP Sheet

- SAP Phasing

- Stretch Film Laminates

- Extremely soft and flexible

- Gluefree Elastics Lamination

- Gluefree Side Sealing

- Top Sheet 3D Embossing

- Servo Repitch System

-

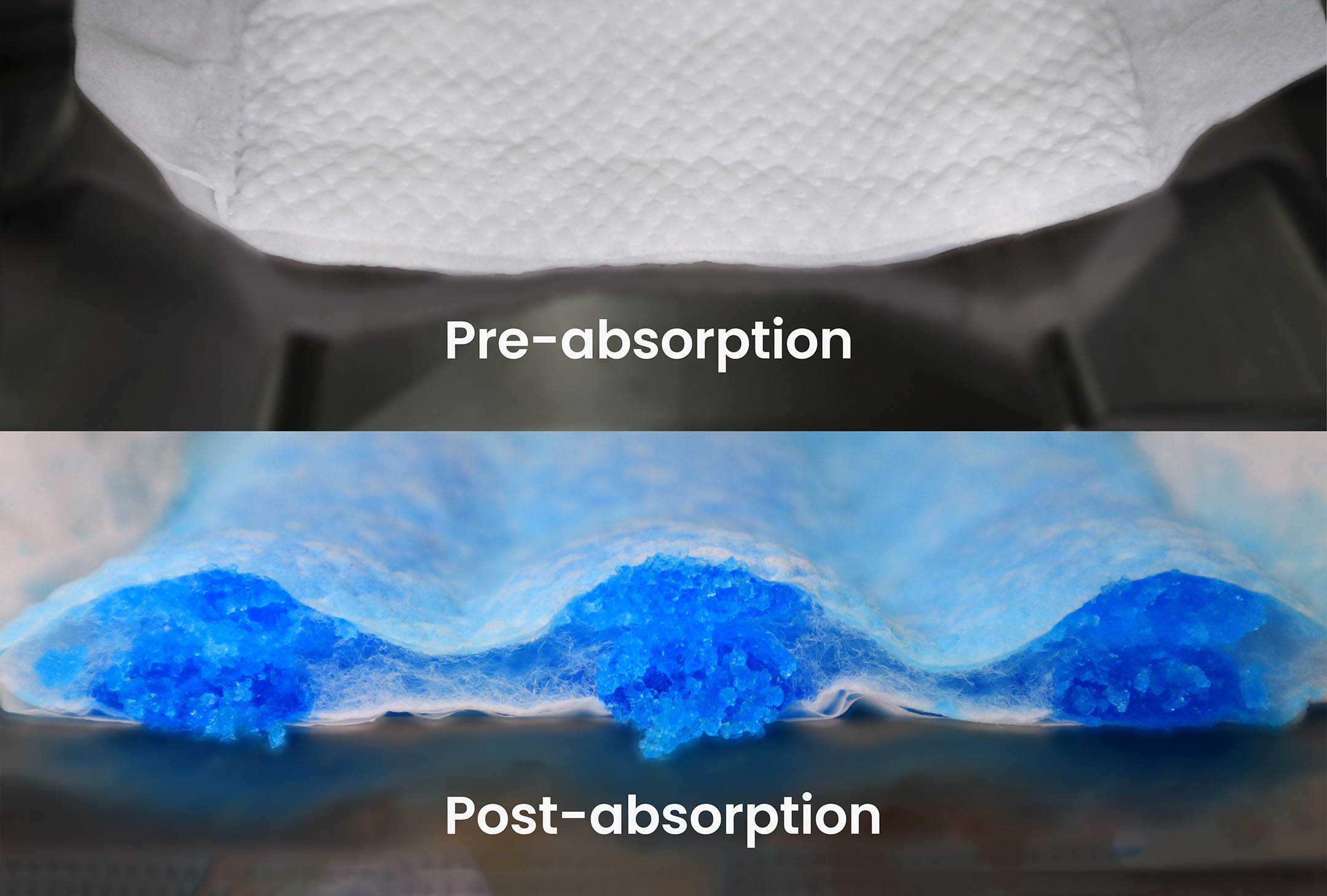

Ultrathin Inline SAP Sheet

High Performance and Cost Friendly Innovation

Introducing the next generation of Super Absorbent Polymers (SAP) sheets made inline. Hybrid Core™ and Double Stream™ SAP Sheets offer customers a choice between thin fluff or fluff-less layered cores. Both SAP sheets diffuse moisture quickly and utilize the entire sheet’s absorbency.

-

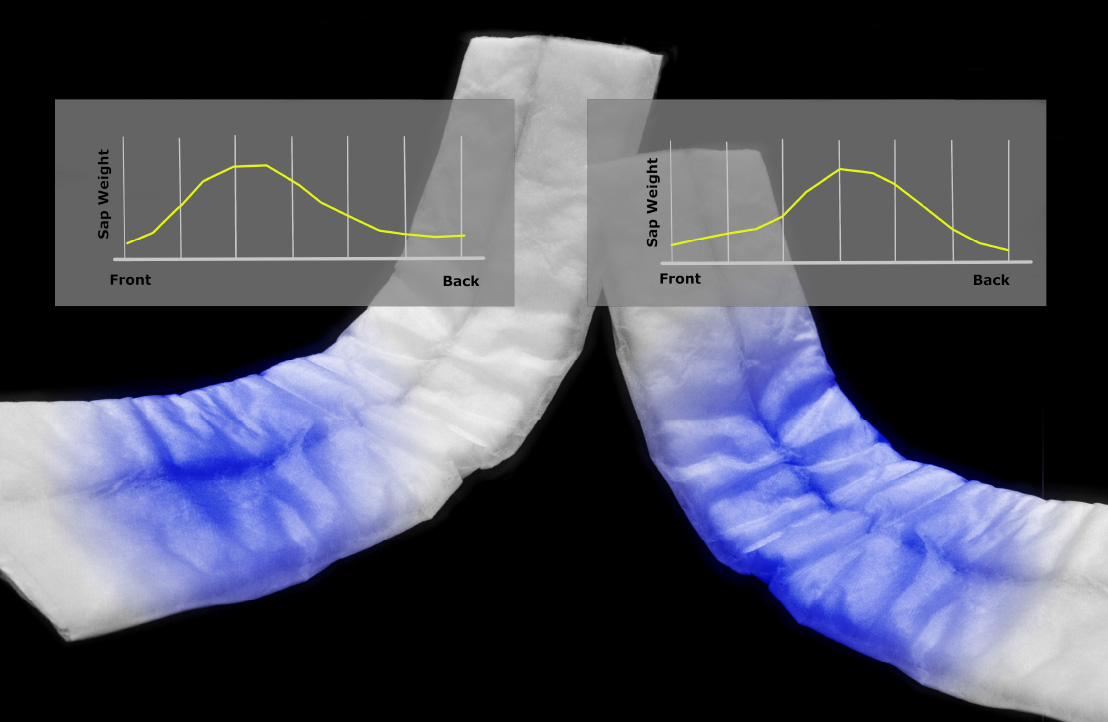

SAP Phasing

Optimizing SAP distribution Inline

Optimizing the distribution concentration of SAP in the absorbent core puts the important material where it is most needed. An absorbent core can be made to perform better for different body sizes and absorption points.

-

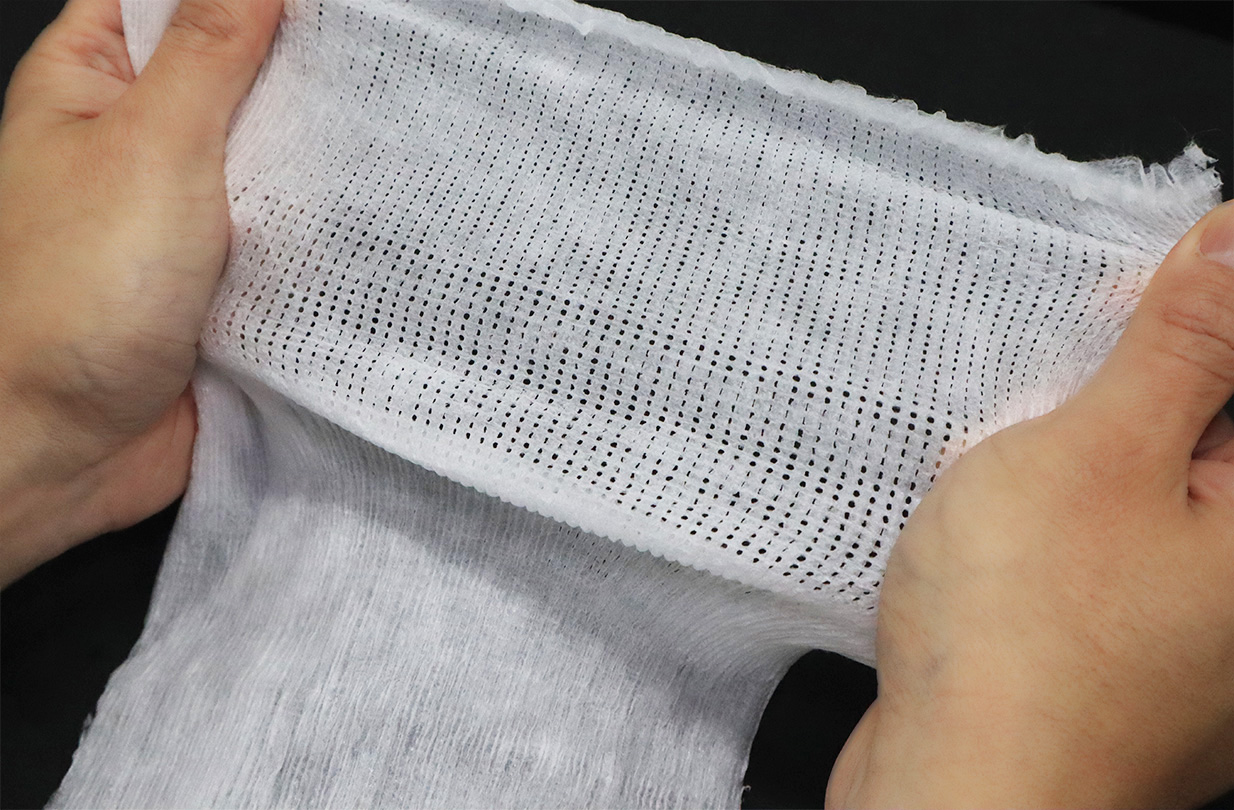

Stretch Film Laminates

Soft, stretchable, and underwear-like

Laminating stretch film to nonwoven materials gives diapers a level of comfort like normal underwear. Soft, stretchy, easy to wear, and fit bodies in all shapes, the material is popular for use in adult diapers.

-

Extremely soft and flexible

Energy-Saving and Production Cost Friendly Sealing Method

Converted from a single piece of nonwoven material, the highly soft and stretchable material is made inline. It is extremely flexible and breathable and applicable to baby and adult diapers for an underwear-like feel.

-

Gluefree Elastics Lamination

Adhesive-less Bonding for Delicate Skin

By securing elastics to nonwoven materials without adhesives, the stretchable material does not harden nor restrict air flow. Using raw materials readily available, its usage in the field is growing.

-

Gluefree Side Sealing

Energy-Saving and High-Speed Sealing

Using less energy than heat sealing methods and requires less resources than hot melt adhesives, the ultrasonic sealing method allows processing soft and robust side seals at speeds of 300 meters per minute. For soft products ultrasonic sealing technologies are used in diapers, sanitary napkins, and various hygiene products.

-

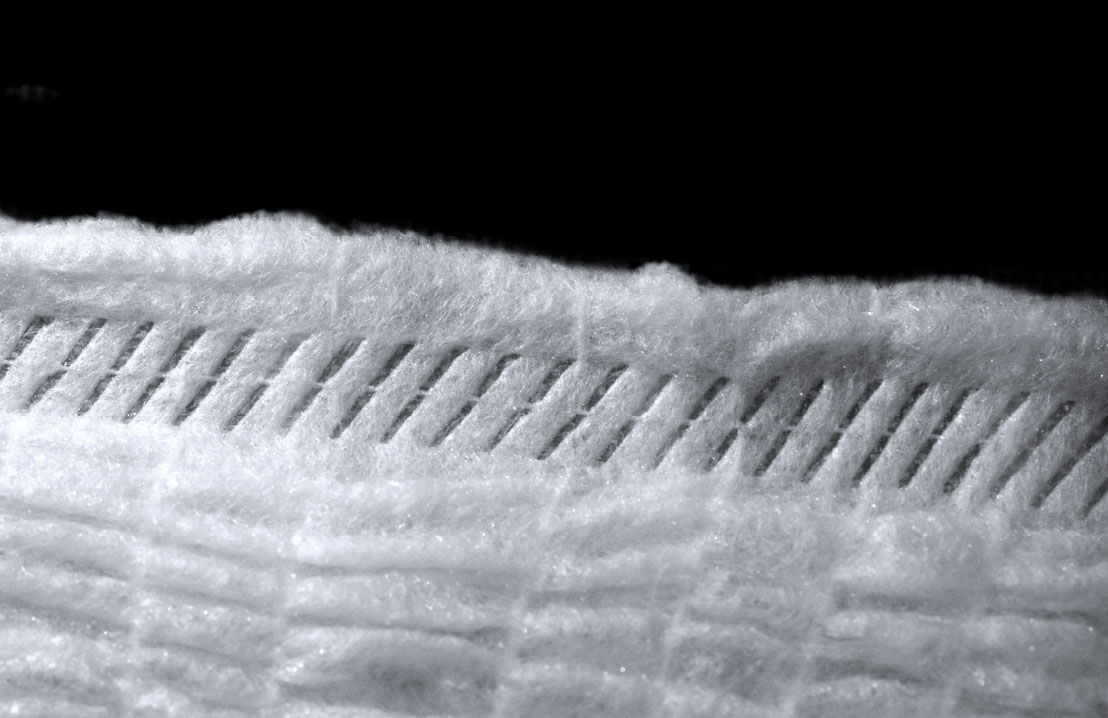

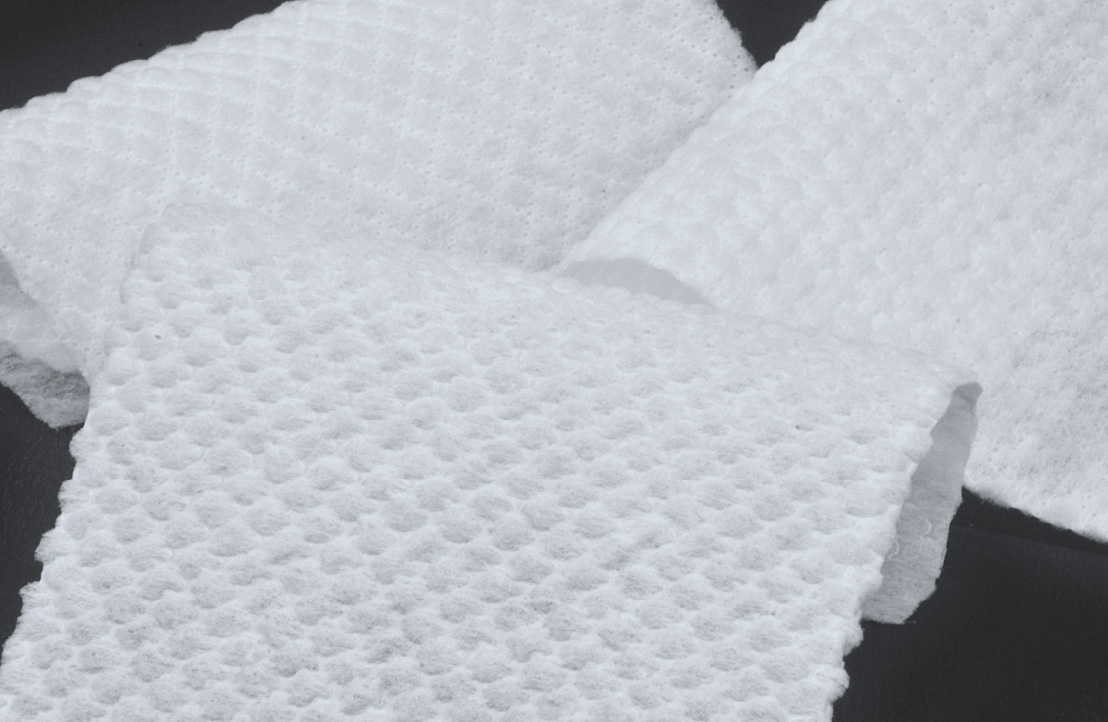

Top Sheet 3D Embossing

Improving Cushioning and Comfort

Often used to soften the top sheet in diapers and feminine napkins, ZUIKO’s embossing technology can convert materials at 300 meters per minute. The system can be installed in the machine for inline production and can be done with one or two nonwoven material layers.

-

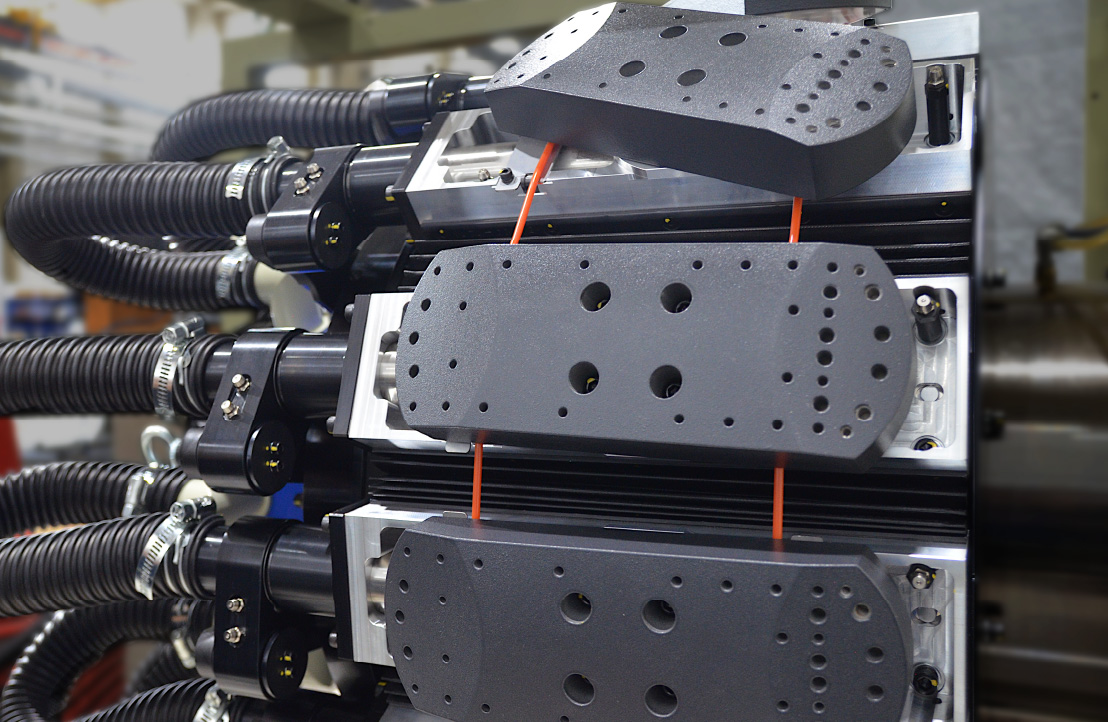

Servo Repitch System

Simplifying the Product Size Change Process

The ability to electronically control and pre-configure the re-pitch system dramatically shortens the downtime needed for product size changes. It is possible to handle a certain range of product shapes and sizes quickly and safely with minimal effort.