Products

Converting Machines|Baby Diaper Machines

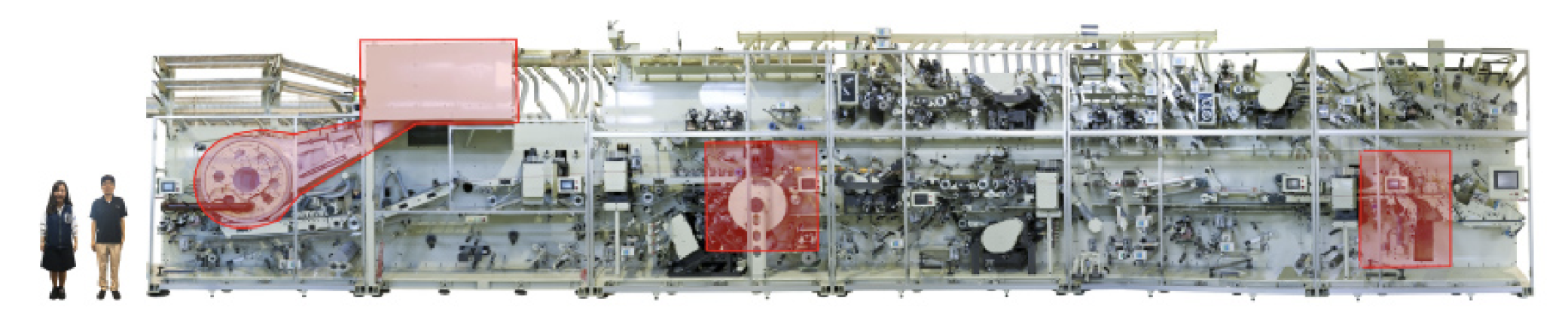

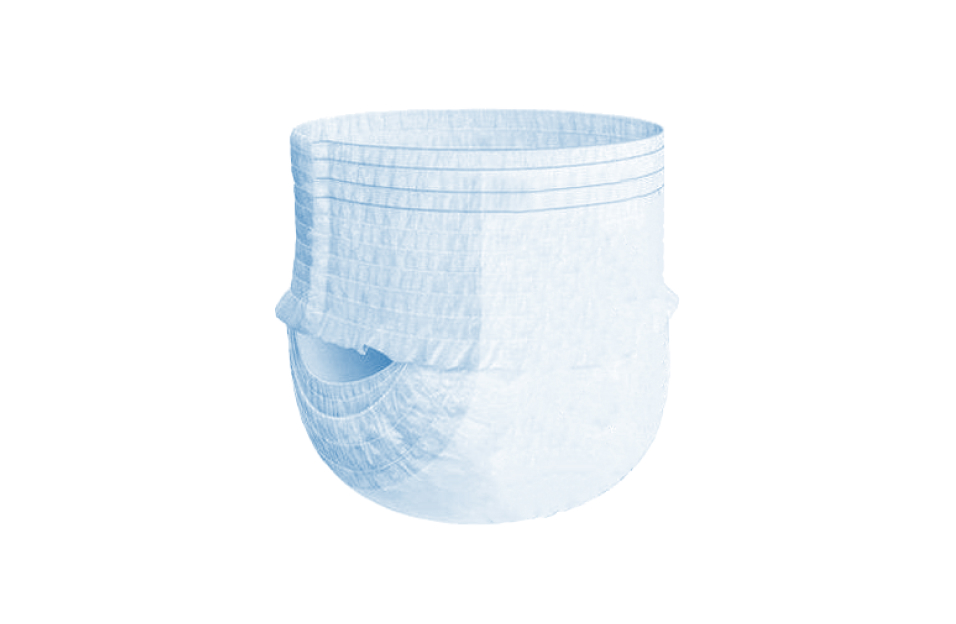

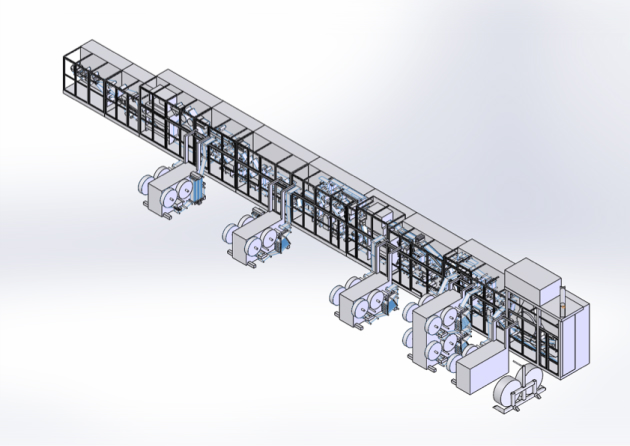

Pants Type Diaper Machines

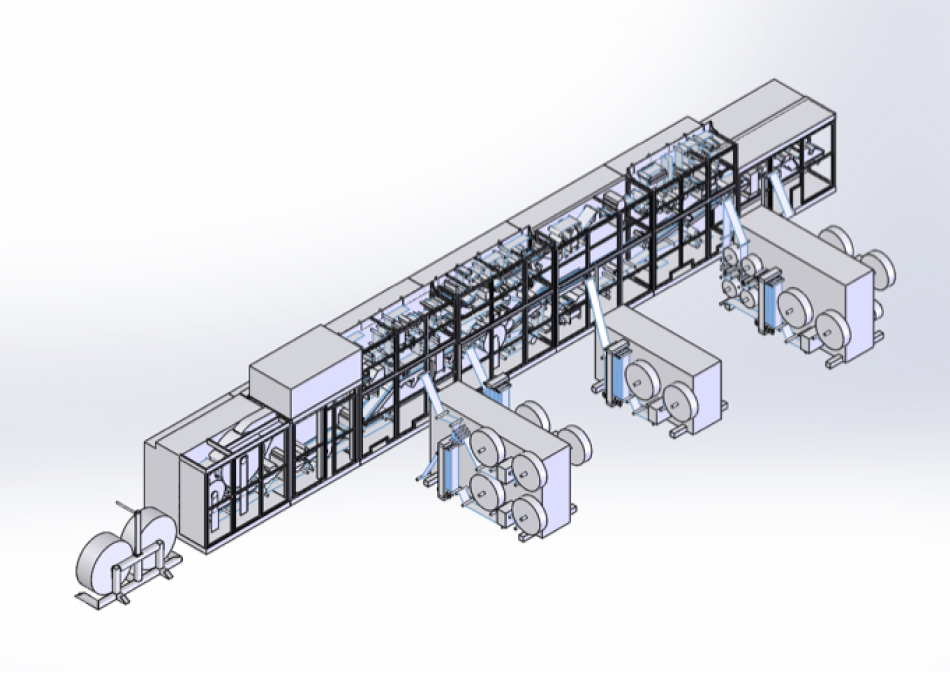

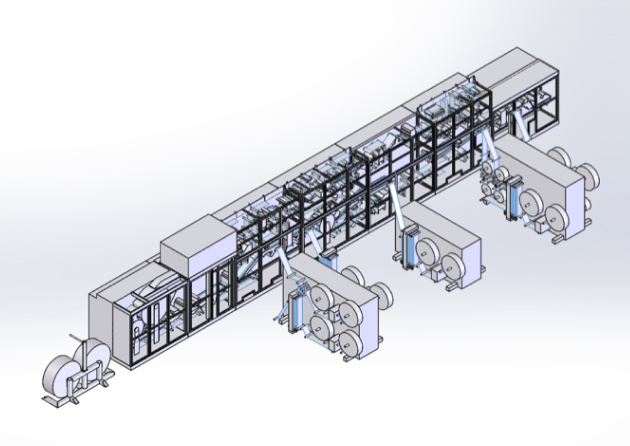

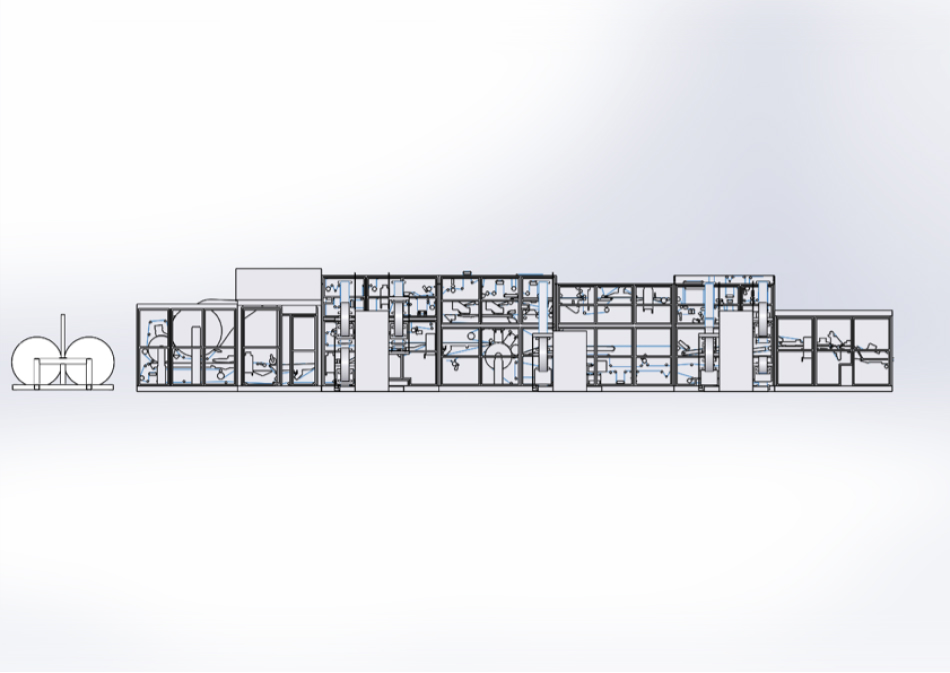

ZUIKO pants diaper machines can use glue-free elastic bonding technologies or other new stretchable material converting methods to improve the comfort, fit, and breathability of the product. Less-material designs and other advanced processes make pants diapers made from ZUIKO machine softer, lighter, and more environmentally sustainable.

Specs

| Production Speed(pieces/minute) | Dimensions(LXWXH) | Product Sizes | Weight | |

|---|---|---|---|---|

| Premium | 1000 | 43m x 11m x 6m | 2 Sizes Possible | Approximately 100-130 Tons |

| Standard | 700 | 37m x 10m x 4m | 5 Sizes Possible |

- Production Speed(pieces/minute)

- 1000

- 700

- Dimensions(LXWXH)

- 43m x 11m x 6m

- 37m x 10m x 4m

- Product Sizes

- 2 Sizes Possible

- 5 Sizes Possible

- Weight

- Approximately 100-130 Tons

- Approximately 100-130 Tons

Basic Specifications

- ・Full Servo Drive System

- ・Absorbent Core Forming System

- ・Auto Splice System

- ・Pulp Fiberizing System

- ・Touch HMI

- ・Safety Door Switches

- ・Power Consumption: 300-600 kVA

- ・Air Consumption: 8,000-12,000 NL/min

Options

- ・Inline SAP Sheet System

- ・SAP Phasing System

- ・Top Sheet 3D Emboss System

- ・Other Options

Image

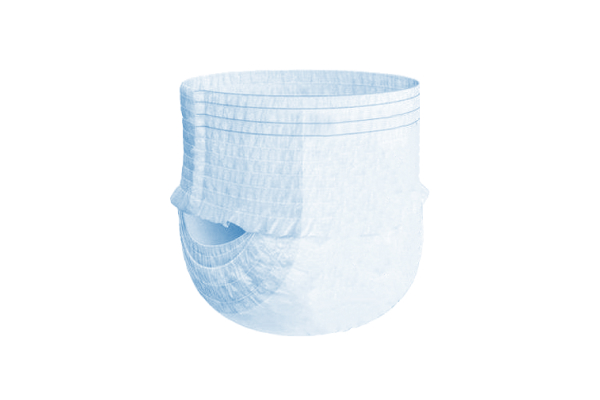

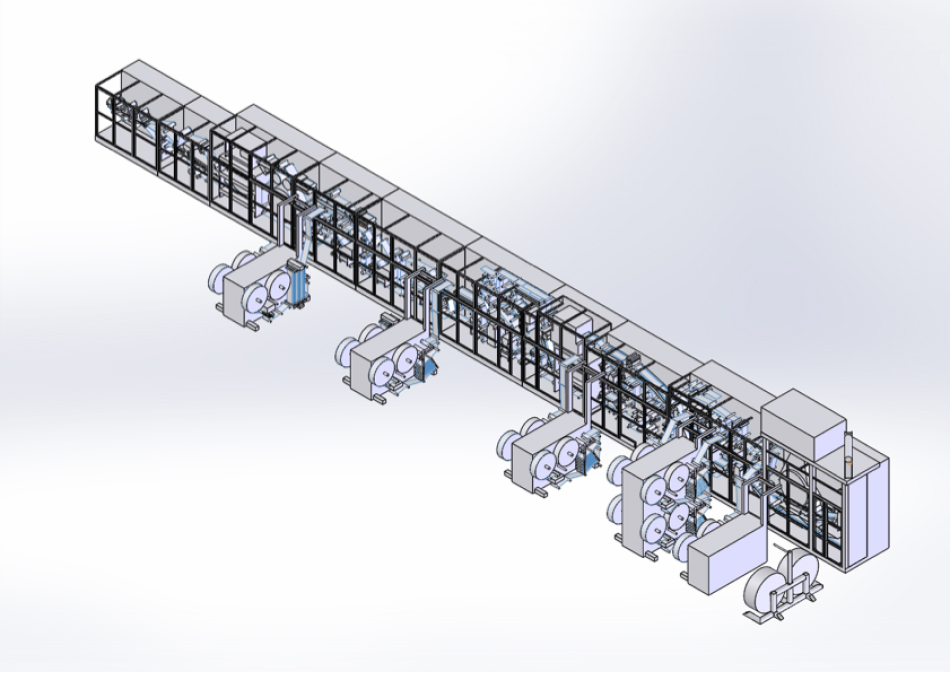

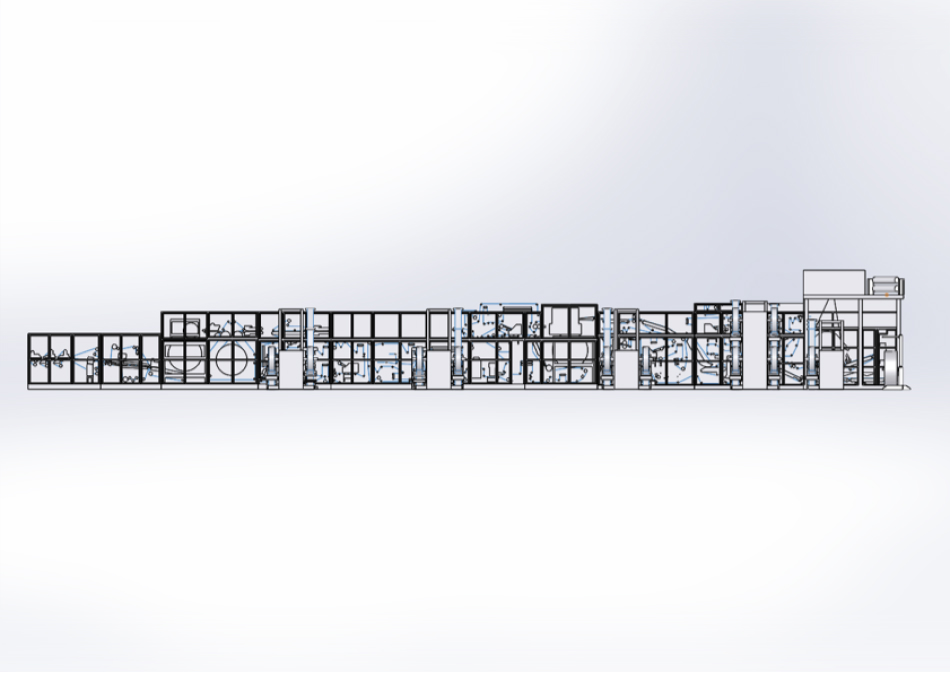

Tape Type Diaper Machines

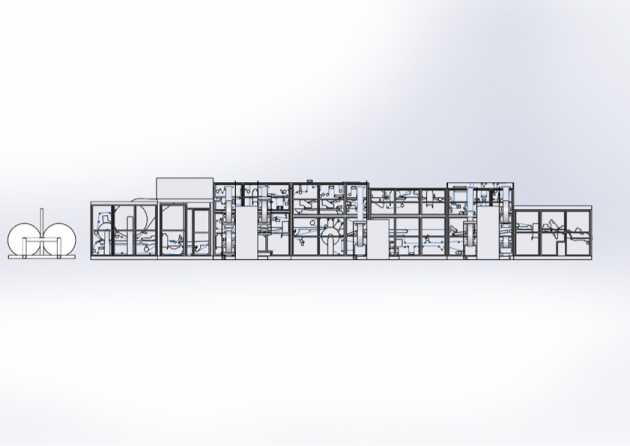

ZUIKO tape diaper machines correctly and precisely cut, place and bond ear tabs on up to 1,000 product chassis per minute. Stable material lamination processes keep production efficiency high and tidy product folding shows a sense of high quality production standards to consumers.

Specs

| Production Speed(pieces/minute) | Dimensions(LXWXH) | Product Sizes | Weight | |

|---|---|---|---|---|

| Premium | 1000 | 40m x 11m x 5m | 2 Sizes Possible | Approximately 100-130 Tons |

| Standard | 700 | 33m x 10m x 4m | 5 Sizes Possible |

- Production Speed(pieces/minute)

- 1000

- 700

- Dimensions(LXWXH)

- 40m x 11m x 5m

- 33m x 10m x 4m

- Product Sizes

- 2 Sizes Possible

- 5 Sizes Possible

- Weight

- Approximately 100-130 Tons

- Approximately 100-130 Tons

- Approximately 100-130 Tons

Basic Specifications

- ・Full Servo Drive System

- ・Absorbent Core Forming System

- ・Auto Splice System

- ・Pulp Fiberizing System

- ・Touch HMI

- ・Safety Door Switches

- ・Power Consumption: 400-600 kVA

- ・Air Consumption: 9,000-13,000 NL/min

Options

- ・Inline SAP Sheet System

- ・SAP Phasing System

- ・Top Sheet 3D Emboss System

- ・Other Options

Image